Cyclone Boys Magnetic Magic Cube Plating 3x3x3 4x4 2x2 Professional Speed Puzzle Toys 3x3 Accessories 3×3 4×4 2×2 Cubo Magico

Sanrio Kuromi Rubik's Cube Key Chain Wholesale Puzzle Cute Anime Accessories Cartoon Kawaii Creative Pendant School Bag Pendant

Wholesale Premium High Quality Smoke Shop Accessories Tobacco 4 Piece Metal Square Rubik′ S Cube Grinder - China Vape, Lithium Battery | Made-in-China.com

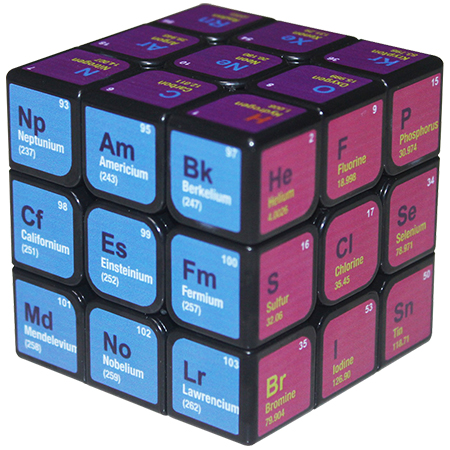

CB Chemical Element 3x3x3 Magic Cube_3x3x3_Cubezz.com: Professional Puzzle Store for Magic Cubes, Rubik's Cubes, Magic Cube Accessories & Other Puzzles - Powered by Cubezz

Amazon.com : Wooden Camera Accessory Cube with Anti-Twist Pins to Mount to Cage or Rig, Compact 1" Cube for Mounting Accessories (1/4"-20) : Electronics