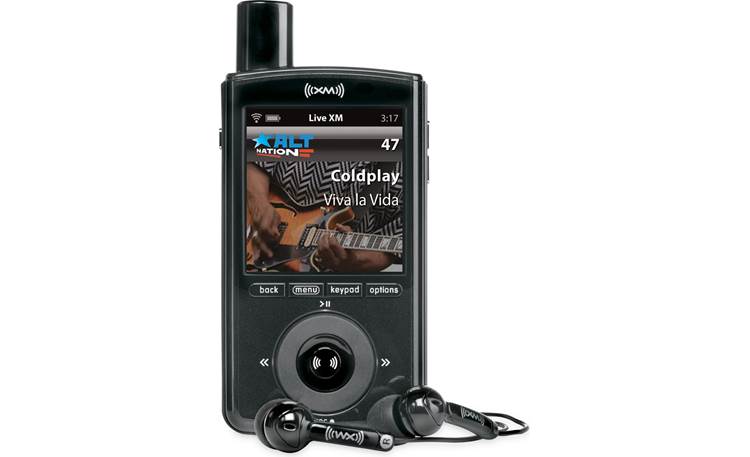

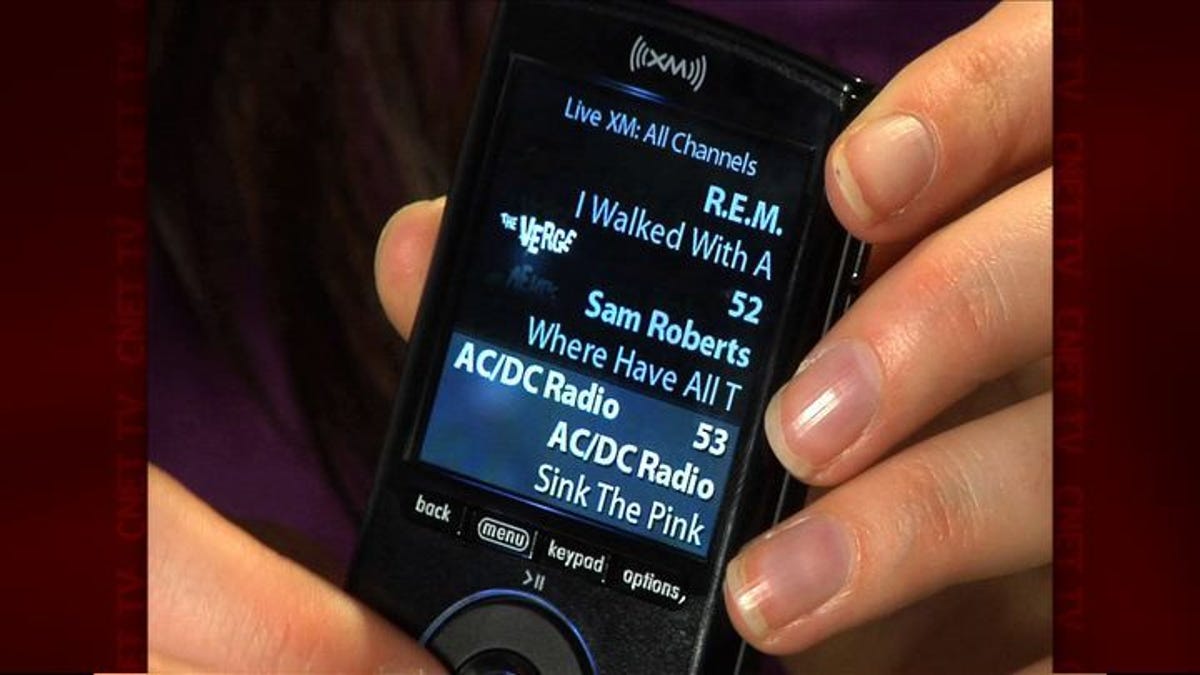

XM XPMP3H1 Portable Satellite Radio and MP3 Player (XMp3i) | Headphone Reviews and Discussion - Head-Fi.org

XM Culture 3 in 1 Bluetooth-compatible 5.0 Neck-Mounted Headset MP3 Player FM Radio TF Card Support - Walmart.com

Samsung Helix/Nexus XM2Go @LightAV.com 877 390-1599 samsung,xm ,satellite,yx-m1z,sattelite,sirius,portable,sattelite,radio,helix,nexus,inno,yx,m1,yp,x5x,x5z,yz-m1,yp-x5x,yp-x5z,cd200,cp200,100,ya, mp3,home,car,dock,kit,samsung,xm,sattelite,sirius ...

![XM to MP3] How to Smoothly Play XM Audio File with the Best XM Converter XM to MP3] How to Smoothly Play XM Audio File with the Best XM Converter](https://www.videoconverterfactory.com/tips/imgs-self/xm-converter/xm-converter-1.jpg)

![XM to MP3] How to Smoothly Play XM Audio File with the Best XM Converter XM to MP3] How to Smoothly Play XM Audio File with the Best XM Converter](https://www.videoconverterfactory.com/tips/imgs-self/xm-converter/xm-converter-3.jpg)