Amazon.com: Ken Hom Carbon Steel Wok, 27cm, Excellence, Induction Hobs Suitable/Metal Tool Safe/Phenolic Handle, Includes 1 x Chinese Wok Pan, KH427001: Home & Kitchen

Amazon.com: Ken Hom Excellence Non-Stick Carbon Steel Wok - Non-Stick Stir Fry Wok - Lightweight Flat Bottom Wok - 12 inch : Everything Else

Amazon.com: Ken Hom Excellence Non-Stick Carbon Steel Wok - Non-Stick Stir Fry Wok - Lightweight Flat Bottom Wok - 12 inch : Everything Else

Amazon.com: Ken Hom Excellence Carbon Steel Uncoated Wok - Uncoated Carbon Steel Wok - Stir-Frying Wok & Pan - Hand Wash Only - 14 inches : Everything Else

Amazon.com: Ken Hom Excellence Non-Stick Carbon Steel Wok - Non-Stick Stir Fry Wok - Lightweight Flat Bottom Wok - 12 inch : Everything Else

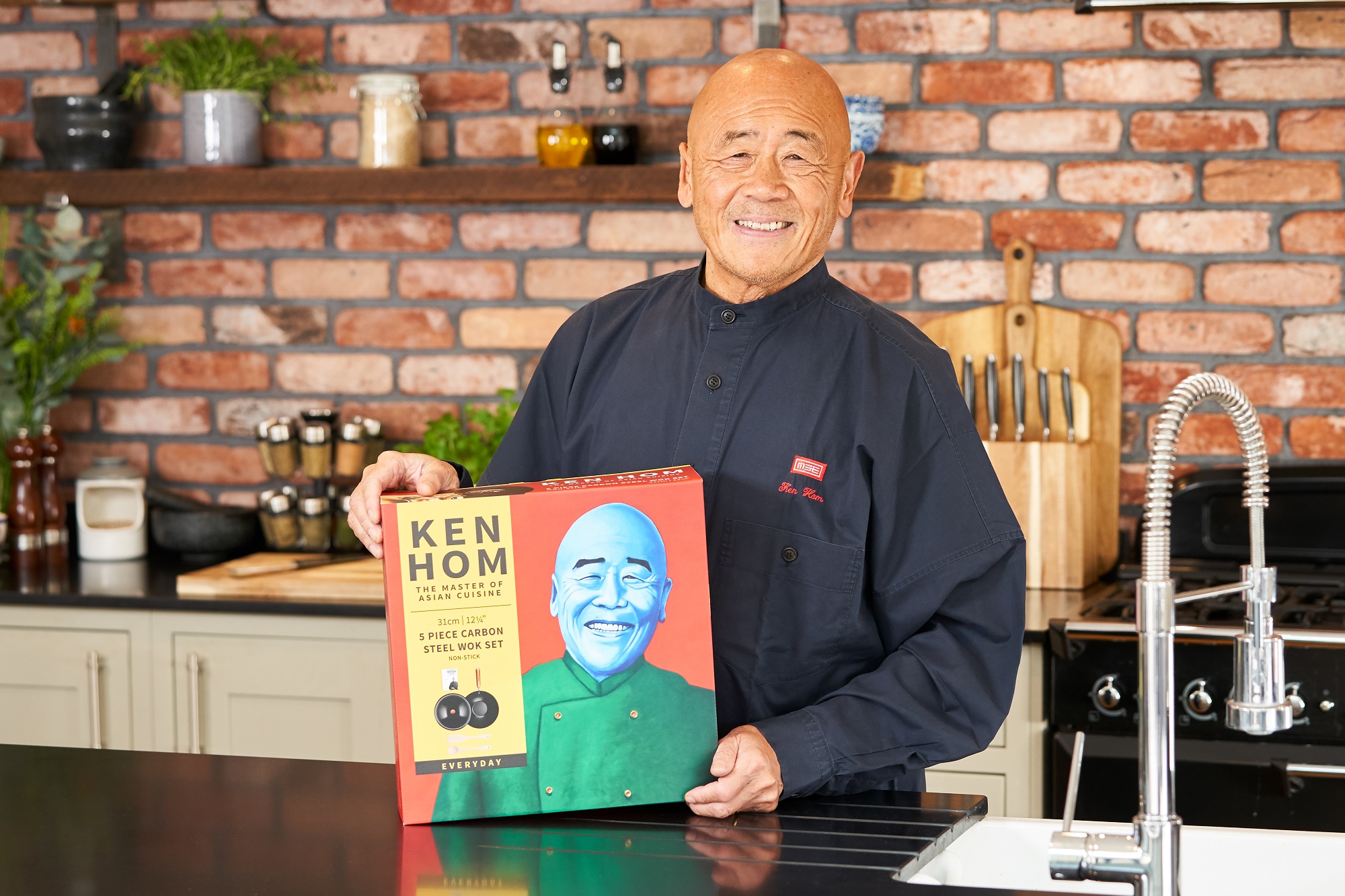

Amazon.com: Ken Hom KH431041 Carbon Steel Non Stick Wok Set | 31 cm | Excellence | Induction Hobs/Metal Tool Safe/Phenolic Handle | Includes Wok With Lid, Wok Utensil & Rack | Dishwasher

Amazon.com: Ken Hom Excellence Non-Stick Carbon Steel Wok - Non-Stick Stir Fry Wok - Lightweight Flat Bottom Wok - 12 inch : Everything Else

Amazon.com: Ken Hom Excellence Carbon Steel Uncoated Wok - Uncoated Carbon Steel Wok - Stir-Frying Wok & Pan - Hand Wash Only - 14 inches : Everything Else

Amazon.com: Ken Hom Excellence Carbon Steel Uncoated Wok - Uncoated Carbon Steel Wok - Stir-Frying Wok & Pan - Hand Wash Only - 14 inches : Everything Else

Amazon.com: Ken Hom Carbon Steel Wok, 31cm, Excellence, Induction Hobs Suitable/Metal Tool Safe/Phenolic Handle, Includes 1 x Chinese Wok Pan, KH431001: Home & Kitchen

Amazon.com: Ken Hom Excellence Carbon Steel Uncoated Wok - Uncoated Carbon Steel Wok - Stir-Frying Wok & Pan - Hand Wash Only - 14 inches : Everything Else

Amazon.com: Ken Hom Excellence Non-Stick Carbon Steel Wok - Non-Stick Stir Fry Wok - Lightweight Flat Bottom Wok - 12 inch : Everything Else

Amazon.com: Ken Hom Excellence Carbon Steel Uncoated Wok - Uncoated Carbon Steel Wok - Stir-Frying Wok & Pan - Hand Wash Only - 14 inches : Everything Else

Amazon.com: Ken Hom Excellence Non-Stick Carbon Steel Wok - Non-Stick Stir Fry Wok - Lightweight Flat Bottom Wok - 12 inch : Everything Else