EXCAVATOR / DIGGER samt POWER CRANE, 2 stycken, Lego, Technic, 8853 och 8854, lanserade 1988 respektive 1989. Bägge med manualer. 8854 med originalkartong. Leksaker - Leksaker - Auctionet

![LEGO Technic 42156 PEUGEOT 9X8 24H Le Mans Hybrid Hypercar - Worth the hype? [Review] - The Brothers Brick | The Brothers Brick LEGO Technic 42156 PEUGEOT 9X8 24H Le Mans Hybrid Hypercar - Worth the hype? [Review] - The Brothers Brick | The Brothers Brick](https://s3-us-west-2.amazonaws.com/media.brothers-brick.com/2023/05/LEGO-42156-PEUGEOT-9X8-24H-Le-Mans-Hybrid-Hypercar-TBB-Review-8-1024x683.jpg)

LEGO Technic 42156 PEUGEOT 9X8 24H Le Mans Hybrid Hypercar - Worth the hype? [Review] - The Brothers Brick | The Brothers Brick

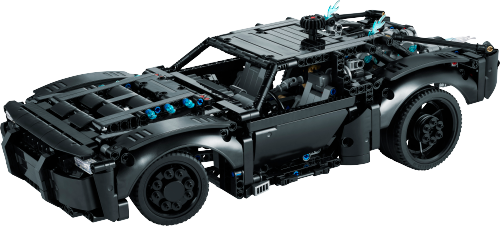

THE BATMAN - BATMOBILE™ 42127 - LEGO® Technic - Building Instructions - Customer Service - LEGO.com US